Description

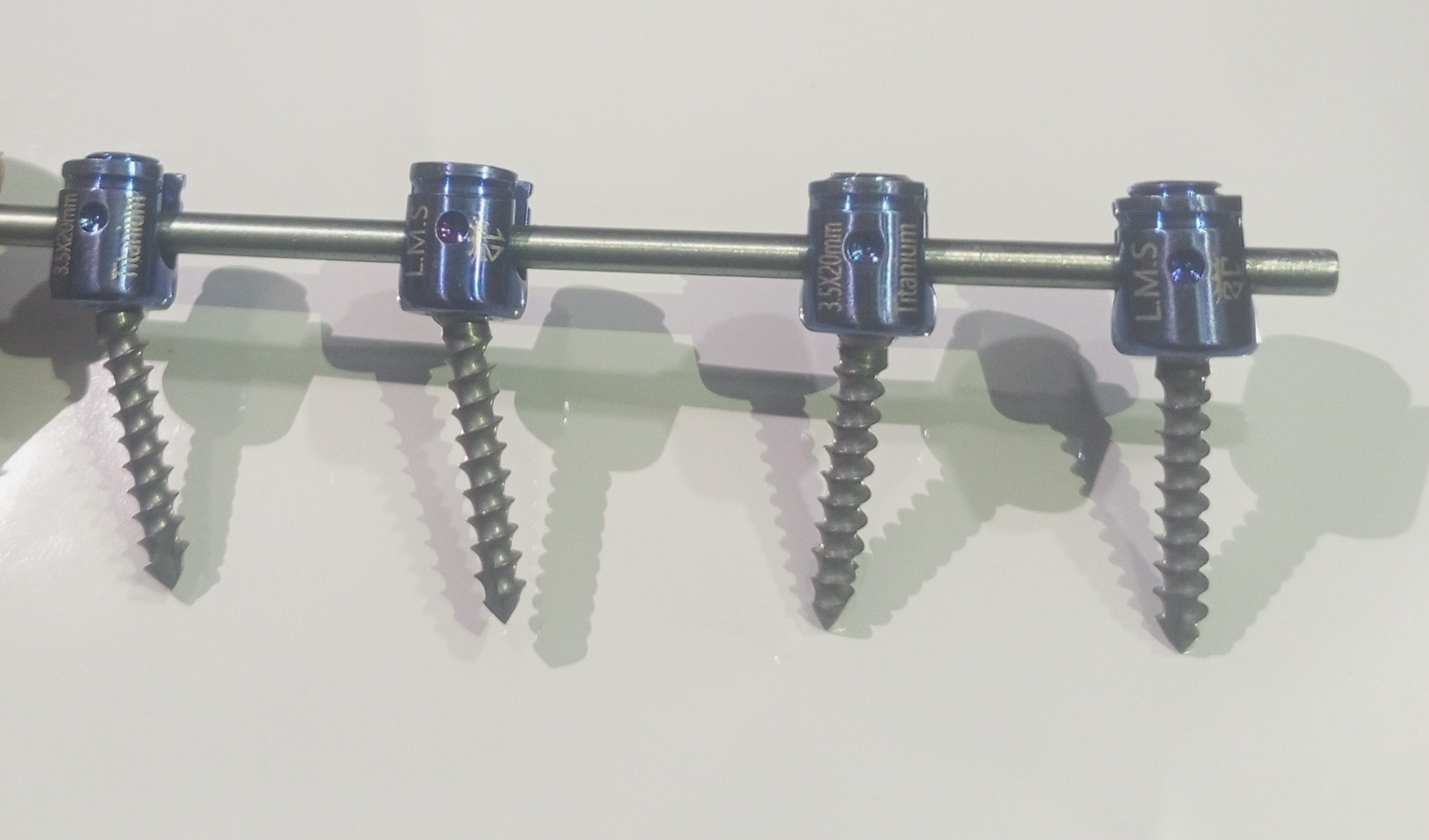

In the field of orthopedic and spinal surgery, the use of advanced fixation systems is critical for achieving stability, promoting healing, and ensuring patient recovery. One such innovative component is the 3.5mm polyaxial Little Mess screw, which has gained popularity among surgeons for its versatility, precision, and ease of use. These screws, available in sizes ranging from 12mm to 22mm, are designed to provide superior fixation in complex anatomical structures, particularly in trauma and reconstructive procedures.

This article explores the design, features, and benefits of 3.5mm polyaxial Little Mess screws, highlighting their role in improving surgical outcomes and patient care.

What Are Polyaxial Screws?

Polyaxial screws are orthopedic screws that allow for multidirectional movement of the screw head relative to the screw shaft. This flexibility enables surgeons to adjust the screw angle, making it easier to achieve proper alignment and fixation, even in challenging anatomical positions.

In the case of Little Mess screws, the polyaxial design is particularly valuable because it:

- Accommodates anatomical variability – Surgeons can adjust the angle to fit different bone shapes and structures.

- Enhances stability – The screw head can pivot, allowing for more secure engagement with rods or plates.

- Reduces surgical time – The flexibility makes it easier to position and secure the screws accurately.

Specifications of 3.5mm Polyaxial Little Mess Screws

The 3.5mm polyaxial Little Mess screws are available in lengths ranging from 12mm to 22mm, making them suitable for a wide range of surgical applications.

Key Specifications:

| Parameter | Details |

|---|---|

| Diameter | 3.5mm |

| Length Range | 12mm to 22mm |

| Material | Titanium alloy (Ti-6Al-4V) or Stainless Steel |

| Head Type | Polyaxial (multi-directional) |

| Thread Type | Dual-threaded for better grip and pull-out strength |

| Coating | HA (Hydroxyapatite) or TiN (Titanium Nitride) coating for improved biocompatibility |

Design and Engineering

The design of the Little Mess screws incorporates several engineering advancements aimed at improving performance and ease of use:

✅ Polyaxial Head:

- The head can rotate up to 30–40 degrees in multiple directions, allowing surgeons to fine-tune positioning and alignment during surgery.

✅ Self-Tapping Tip:

- The screw tip is designed to cut through bone, eliminating the need for pre-drilling and reducing surgical steps.

✅ Dual Thread Design:

- The screw threads are engineered to enhance purchase in cortical and cancellous bone, improving pull-out strength and reducing the risk of loosening.

✅ Low-Profile Head:

- A low-profile screw head minimizes soft tissue irritation post-surgery, enhancing patient comfort.

✅ High-Strength Material:

- Made from titanium or stainless steel, the screws offer excellent strength-to-weight ratio and biocompatibility.

Applications

3.5mm polyaxial Little Mess screws are widely used in various orthopedic and spinal procedures, including:

🔹 Spinal Fusion:

- Used to stabilize the vertebrae during fusion procedures.

🔹 Trauma Fixation:

- Ideal for securing fractures in small bones such as the wrist, ankle, and clavicle.

🔹 Reconstructive Surgery:

- Used in cases where precise alignment and stability are critical.

🔹 Pediatric Orthopedics:

- The smaller size and flexible head make them suitable for pediatric cases with delicate bone structures.

Benefits

The 3.5mm polyaxial Little Mess screws offer numerous benefits for both surgeons and patients:

✅ Improved Surgical Flexibility:

- The polyaxial design allows for greater freedom in positioning and angling, accommodating complex anatomical variations.

✅ Enhanced Bone Purchase:

- The dual-thread design and self-tapping tip ensure a secure grip in both cortical and cancellous bone.

✅ Reduced Risk of Screw Back-Out:

- The secure engagement minimizes the risk of loosening over time.

✅ Faster Recovery Times:

- Improved fixation and reduced surgical time lead to faster healing and rehabilitation.

✅ Minimized Soft Tissue Irritation:

- The low-profile head reduces the risk of discomfort and tissue irritation post-surgery.

Challenges and Considerations

While polyaxial Little Mess screws offer many advantages, there are some considerations to keep in mind:

🔸 Cost:

- Polyaxial screws are generally more expensive than monoaxial screws due to their complex design.

🔸 Technique Sensitivity:

- Proper placement requires precise surgical technique to avoid misalignment or poor fixation.

🔸 Material Compatibility:

- Titanium screws are more biocompatible but may have slightly lower strength compared to stainless steel.

Conclusion

The 3.5mm polyaxial Little Mess screws, available in lengths from 12mm to 22mm, represent a significant advancement in orthopedic fixation technology. Their polyaxial head design, dual-thread construction, and high-strength materials make them a preferred choice for complex trauma and reconstructive surgeries. By providing greater flexibility, enhanced bone purchase, and reduced soft tissue irritation, these screws help surgeons achieve optimal surgical outcomes and improve patient recovery.

For orthopedic professionals looking to enhance surgical efficiency and patient care, the 3.5mm polyaxial Little Mess screws offer a versatile and reliable solution.

Reviews

There are no reviews yet.